FLOORING MATERIALS

GRANITES –

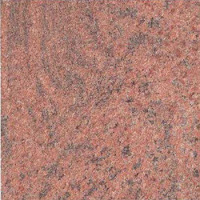

Granites are one of the most common materials used for flooring due to it aesthetic as well as functional properties. It is used extensively in residences as well as other commercial projects, office spaces etc. Different colours are available depending on region and can be used to create interesting patterns

PROPERTIES –

Type of rock – Granite is an igneous rock, meaning, it is formed from molten lava deposits

Density – 2700kg/cu.m

Light coloured granites tend to be more porous than dark coloured granites. The effect of this is that lighter granites tend to absorb more water. Hence, while using lighter coloured granites, proper water sealer has to be applied on all 6 sides to ensure that water is not absorbed.(Water absorption will cause discolouration and marks to appear which will lead to a bad appearance).

Stages of Granite Processing –

1. Rocks & boulders from the mountain quarries are extracted by blasting & dressed as stone blocks of suitable sizes.

2. These blocks of granite are taken to the factory, where they are cut into slabs of required thicknesses by gangsaw or vertical cutters.

3. These slabs are then polished to the required finish at the factory by machines.

4. The larger slabs are then cut to the required sizes at the site, for laying in the required pattern.

TYPES OF GRANITES –

· Grey series – Sadheralli grey, Steel grey, May flower

TYPES OF FINISHED POSSIBLE –

· Polished finished - The granite is polished to a mirror like finish and should have a reflection of 95% when tested with a Glazometer

· Honed finish - This is a non-reflective dull sheen finish done by rubbing the stone with a series of abrasives.

· Textured finish - This is a rough finish which is the natural finish of the stone after quarrying.

· Flamed finish - Flaming is done with the help of an oxy-acetylene torch. It creates a slightly rough finish & is especially used for stones used in the exterior, like pavements etc, to avoid slipping.

· Sandblasted finish - Sandblasting is done by forcing small particles of sand onto the stone surface at very high pressure creating a slightly textured finish.

· Chiselled finish - This is made by chipping off small pieces of stone with the help of a chisel and produces a very textured, heavy appearance.

NORMAL THICKNESSES OF SLABS –

10mm, 20mm, 30mm, 40mm etc.

PRICE RANGE OF COMMON GRANITES –

Granite prices range from around Rs150/sq.ft to over Rs.300/sq.ft

TYPES OF JOINTS POSSIBLE –

Granite can be laid either with Butt joint (i.e no spacing) or grooves can be provided between the stone slabs, which can later be filled with grout. Care to be taken that spacers of required thicknesses are to be used while creating the grooves, to ensure proper line and joints. This is to be included in the specifications itself.

PREPARATION OF AN ARCHITECTURE PORTFOLIO

I have been receiving a lot of requests from students for details on HOW TO PREPARE A GOOD ARCHITECTURE PORTFOLIO.

Taking this into consideration, I have compiled a detailed booklet on how to create a great portfolio, which will guide you through the detailed process, including identification of materials, ideal layouts, graphics and rendering styles, text placements, photographing your models....an exhaustive list which will guide you step by step.

You can now avail this great resource for creating your best portfolio, which is essential in this highly competitive age - either to get into good firms for internships, applying for your masters or for getting that coveted job.

Get full access to 'How to prepare an Architecture Portfolio' !!!

So go ahead and mail me at ar.sujithgs@gmail.com to order today!

Nice information on flooring granite. The information about the types of finished possible in flooring granite is very informative because there are few people know about this process which are applying to the granite. However recently I was use the blue series simple floor granite in my bathroom which are ordering from builderoutletusa.com.

ReplyDelete